Boost Project Accuracy with Professional CAD Detailing Services

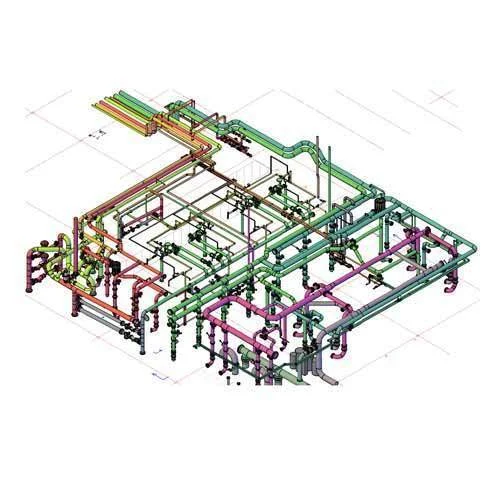

In construction and manufacturing, accuracy isn't just a technical standard — it’s the difference between profit and loss, between deadlines met and projects stalled. As buildings, systems, and products become more complex, the need for precise, coordinated, and constructible documentation is greater than ever. Enter professional CAD detailing services — the unsung heroes behind seamless execution on job sites around the world. In this article, we’ll dive into how CAD detailing elevates project accuracy, minimizes risk, and plays a crucial role in modern project delivery. What Is CAD Detailing? CAD (Computer-Aided Design) detailing is the process of developing highly detailed technical drawings that communicate precise information about a structure, component, or system. It transforms basic schematics or conceptual designs into fully annotated blueprints that can be used in fabrication, construction, or manufacturing. CAD detailing involves: Accurate 2D and 3D drawings Dime...